MEP (Mechanical, Electrical, and Plumbing) Design Validation is the process of profoundly checking and validating the designs set by the customers. It validates the entire structure before constructing it in the actual space. All such validation processes at Geninfo Solutions are handled by our expert team of engineers and architects. Under the MEP Design Validation, our experts check for the trade-related conflicts, deformities in the design, and entire expense cutting

The MEP Design Validation and MEP Coordination Services are done smoothly, ensuring that many potential risks or errors are removed from the roots. As a result, there are the most negligible chances of construction risks. For this purpose, the BIM tools are generally used to ensure Energy saving, huge designs, and cost-cutting alternatives, which is the ultimate result of using the BIM tools.

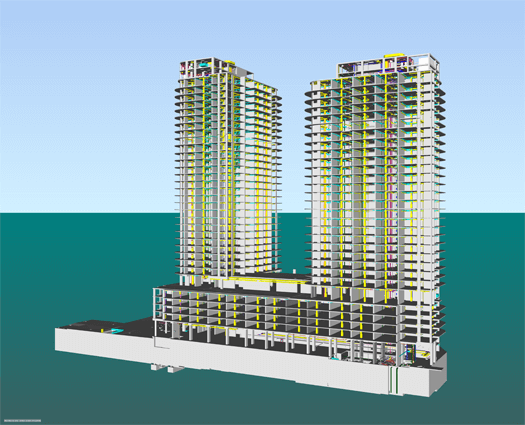

As a part of Geninfo’s coordination process for Mechanical, Electrical, and Plumbing (MEP) systems on complex buildings and light industrial projects we offer improved integration by defining locations for branch components of systems in congested spaces to avoid interferences and comply with diverse design and operations criteria.

GenInfo Solutions provides unparalleled and remarkable MEP BIM Services. From the MEP Design Auditing to MEP Design Drawings, we help define the location for major system components in sophisticated places, providing an improved level of an integrated environment.

Geninfo Solutions has been providing outstanding MEP BIM Services since 2008. Geninfo Solutions strives to produce excellent results by giving the MEP Design Validation and Coordination Services the most innovatively. Verification and assurance of the BIM Modelling Services are smoothly and efficiently handled by our expert team of architects and qualified engineers.

At Geninfo Solutions, we use documented procedures and the RFI - Request for Information responses to validate. Our highly skilled team of MEP Modelling, BIM Modelling Services, and other Arch Design Validation experts bring forth the timely delivery of the Architectural Rendering Services and MEP BIM Services. Constructability Analysis is the core part of our entire process, to unravel all the errors for implementing the smooth construction process.

Our team reviews the minor details before the actual building construction takes place, leading to a negligible amount of risk in construction. Using coordination drawings and 3D BIM Models, we provided the best fabrication & completion of the installment process. Customer focussed approach is well maintained from the beginning to the last date by Geninfo Solutions. Contact us now to understand us better and start working once we get the zest of your project idea!

The complete full form of an MEP is 'Mechanical, Electrical and Plumbing' concerning the construction field. The three listed technical elements help construct the building, which will be livable for human beings. Without any doubt, the impressive interaction between them makes the MEP installations get composed concurrently. It further leads to staving off struggles related to the location of tools.

MEP BIM Services is the way to formulate the 3D models that are knowledge enhanced and are particularly pointed towards the construction building's electrical, mechanical, and plumbing facets. The information enriched MEP BIM Services helps to strengthen the preciseness level. Moreover, it brings forth all the relevant data to minimize the conflicts and augment the MEP Coordination. The MEP BIM Services include MEP CAD conversion, MEP 3D Modeling, As-built drawings, etc.

MEP Drawings tell us how MEP Components will be designed along with what they will be functioning. MEP Drawings built the structures that are energy competent & RDS efficient. Working on projects utilizing the MEP Drawings is adopted by subcontractors, MEP Engineers, Designers, Architects, Construction contracting parties, Manufacturers & its Suppliers. They use it to provide an overall symmetry, fabrication, and installation specifications in the MEP Services, for example, sheet metal duct, piping, and safety against fire. The MEP Drawings are conflict-settled and well-coordinated. There are several types of MEP drawings like coordination drawings, as-built drawings, detailed shop drawings, penetration drawings, and pipe spool drawings.

AutoCAD can't be considered an MEP BIM directly; instead, it's a facilitator of MEP BIM. The central point segregating the AutoCAD and MEP BIM is the CAD - Computer-Aided Design. Similar to the ones elicited in the AutoCAD software, it is generally utilized as a drawing tool, making it crucial for BIM systems. In addition, Revit MEP, on the other hand, provides an effective plan to design and report.

MEP coordination services are vital to ensure that mechanical, electrical, and plumbing systems are properly planned, designed, and installed, reducing conflicts, optimising space, and enhancing overall project efficiency.

Software tools commonly used in MEP coordination services include Building Information Modeling (BIM) software, clash detection software, and collaboration platforms to facilitate coordination and communication among project stakeholders.

MEP coordination services contribute to the creation of accurate as built drawings by ensuring that the installed MEP systems are properly coordinated, reflected, and documented in the final drawings.

Yes, coordination drawings serve as valuable references during facility maintenance by providing a visual representation of the installed systems, aiding in locating components, understanding connections, and facilitating repairs or upgrades.

Coordination drawings are typically created by specialized professionals, such as MEP (mechanical, electrical, plumbing) coordinators or BIM (Building Information Modeling) specialists, who have expertise in system coordination and design.

Coordination drawings are drawings that show the spatial relationship and coordination between different building systems, such as structural, mechanical, electrical, and plumbing.

Coordination drawings serve as a reference during construction and are often updated to reflect any changes made during the process, forming the basis for accurate as built drawings that document the final layout of the coordinated systems.